- Large variety of sizes and drive types

- Ready-to-mount linear systems

- Different guide systems and drive types

- Suitable accessories such as couplings, motor flanges, connecting shafts, etc.

- Simple and versatile combination possibilities, even of different sizes, to multi-axis systems

HERE YOU WILL FIND THE GIA MODULES AND DRIVE COMPONENTS

GIA MODULES

Internally developed and customisable GIA products.

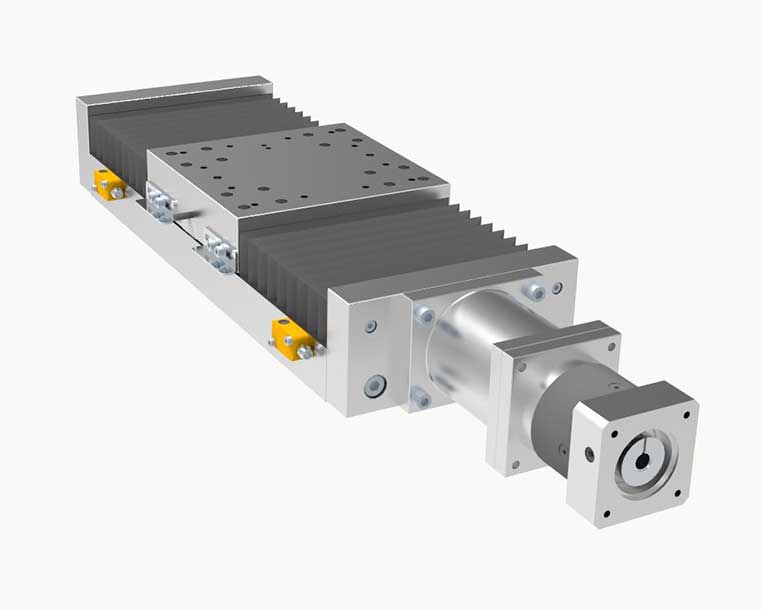

LVE | Linear Actuator LVE ECO | Linear Actuator

KR + KK | Compact Linear Unit LPT + PPT | Precision Positioning Table

Bevel Gear Screw Jack

LVE | Linear Actuator

-

Belt drive (LVE 65 / 80 / 100 / 180 / 360)

The belt drive is preferably used for tasks requiring high speed with medium loads and precision. The belt is guided through flaps on the sides and prestressed at the guide carriage. Special antiturn washers make sure the drive is backlash-free and therefore guarantee high repeatability even in case of long ways and high speed. The tooth belt is made of polyurethane and features tensile members made of steel braids – providing sufficient safety for higher loads.

Ball screw drive (LVE 65 / 80 / 100 /180 / 360)

Ball screw drives can be found wherever high feed forces and precision with medium speed are required. The ball screws are available with low or no backlash.

Trapezoidal screw drive (LVE 65 / 80 / 100 /180 / 360)

Trapezoidal screw drives are recommended solutions for medium precision and speed. The duty cycle should not exceed 30 % per hour.

Gear rack drive – on request (LVE 180 / 360)

Gear rack drives can be used to drive several carriages on one guide independently of each other. High speeds with medium positioning precision are possible.

LVE ECO | Linear Actuator

- Cost-effective linear actuator

- Ready-to-mount linear system

- Proven quality of GIA LVE systems

- Recirculating ball bearing guides

- Simplified motor and gear mounting

- Suitable accessories such as motor flanges, proximity sensor fastening, connecting shafts, etc.

- Simple combination to multi-axis systems

The linear actuators are available with profile dimensions of 30 / 50 / 80 mm.

KR + KK | Compact Linear Unit

- Ready-to-mount linear actuator

- High performance with smallest dimensions

- Two linear guides integrated in the profile

- Linear guide rails in 3 dimensions 15, 20, or 25 mm

- Optionally available with short or long carriage

- Central lubrication system

- Optionally with tooth belt (KR) or with ball screw (KK)

- 3 profile widths 110, 145 and 200 mm

- Suitable accessories such as clamping strips, motor flanges, couplings, etc.

- Combination to multi-axis systems possible by means of connecting plates

- Support profile made of aluminium, no fixed lengths

LPT + PPT | Precision Positioning Table

- Ready-to-mount drive module

- Suitable for absorbing high torques and axial loads

- High positioning precision possible

- High stiffness with correct design

- Optionally with ball screw or trapezoidal screw drive

- Block bearings with tapered roller or double-row angular contact ball bearings depending on load

- Central lubrication system

- Suitable accessories such as motor flanges, couplings, proximity sensor mounting, etc.

- Protection of guides and screw drives with bellows or sheet metal cover

- Simple combination to multi-axis systems possible

- Custom versions available

-

Positioning tables LPT

The modular construction consists of a carriage made of an aluminium alloy with four sealed linear slides and two hardened and precision-ground guide shafts made of steel or stainless steel. The linear slides are aligned in a way to absorb loads from all directions.

The LPT positioning tables are available with shaft dimensions of 08 / 12 / 16 / 20 / 25 /30 /40 /50 mm.

Positioning tables PPT

The positioning tables are available in aluminium and steel versions. All seatings for the guides, the underside of the base plate and the top side of the slide are precisely machined. Ball or roller guides can be used as guiding system according to the load.

The PPT positioning tables are available as standard with the guide sizes

15 / 20 / 25 mm.Other dimensions on request.

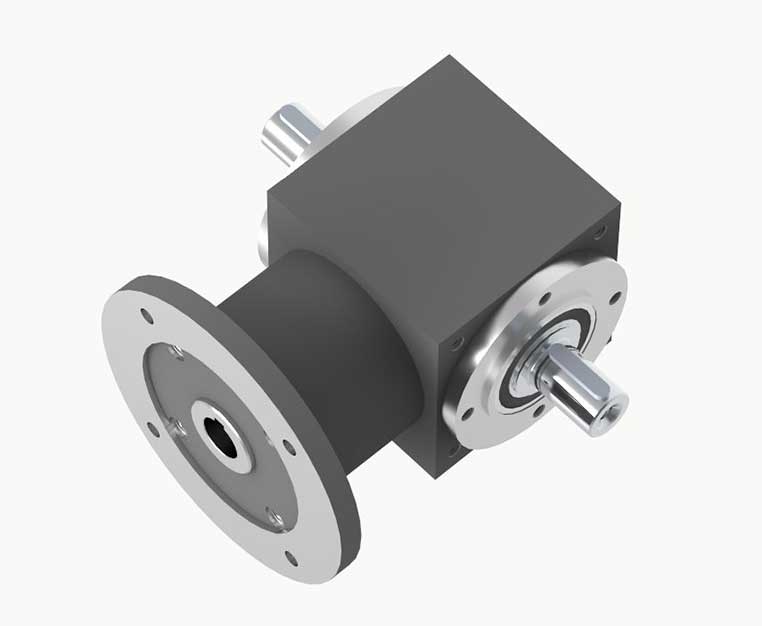

Bevel Gear

- Robust cast iron housing

- Hardened bevel gears lapped in pairs with spiral toothing

- Well-dimensioned roller bearings

- 10 variants are available

- They can be used in all operating positions and provided with mounting holes on all sides

- Their efficiency is 94 to 98 % (depending on speed and operating position)

-

Type V

There are seven standard gear sizes 065 / 090 / 120 / 140 / 160 / 200 / 260 (flange dimension). Drive speeds up to 6000 rpm and output torques up to 2300 Nm are possible.

Type VL

Standard version (as type V) with attached motor flange for

IEC standard motors. Connection with motor via hollow drive shaft with keyway.Type VC

Standard version (as type V) with attached motor flange for

IEC standard motors. Connection with motor via rotationally elastic coupling.Type AD – Servo

Standard version (as type V) with attached motor flange for servo motors. Connection with motor via rotationally elastic coupling.

Special designs

Low backlash design

All bevel gears are available with low backlash.

Standard gear sets are available with the following values:S1: i = 1:1 to 2:1 < 6 arc minutes

S2: i = 3:1 to 6:1 < 10 arc minutes

Torsion angles < 6 arc minutes are available.

(Please contact us.)Non-corrosive gears

Non-corrosive gears are suitable for all applications where the drive is in contact with aggressive substances.

As a standard the housings are nickel-plated and tinned afterwards. The shafts are made of stainless steel. The sealings are adapted to the respective application. For special applications the bevel gears are also available in stainless steel design.

Screw Jack

- Large variety of design variants and sizes (2.5 kN to 500 kN)

- Cubic housing, therefore easy to constructively integrate

- All gears can be subjected to pressure and tension loads

- Extensive accessories for a wide range of mounting situations

- Rust-protected design possible

- Low backlash design possible

- Optionally with ball screw or trapezoidal thread

- With trapezoidal thread self-locking to a limited extent

-

SH-G

The linear stroke is carried out by the fixed screw. The screw is led through the jack axially by turning the worm gear. Twisting of the screw must be prevented by the adjacent construction or a twisting protection installed in the jack (VD version). The load to be moved is attached to the end of the screw.

SH-L

The travelling nut moves up and down on the rotating screw. The screw is fixed in the rotating worm gear. The load to be moved is fastened to the travelling nut.

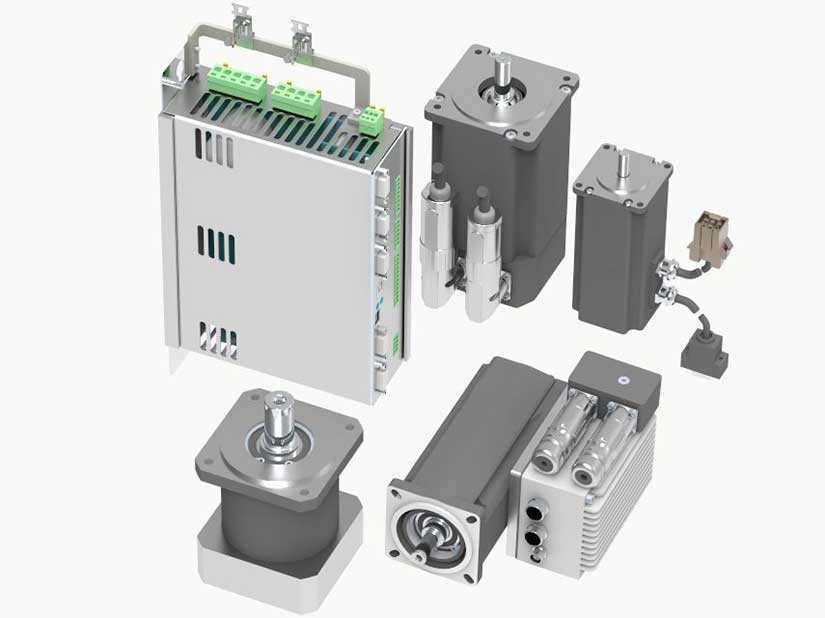

DRIVE COMPONENTS

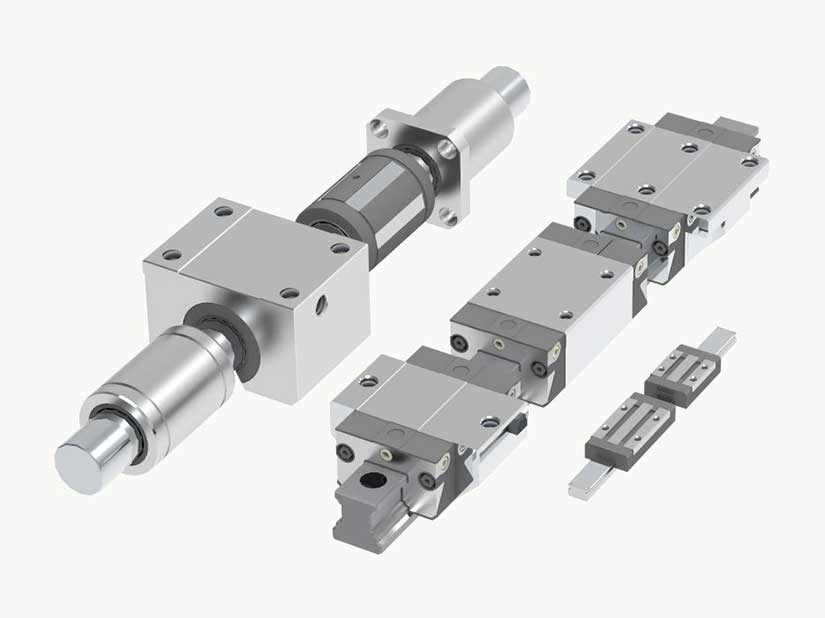

Ball Screw Drive + Trapezoidal Screw Drive + Accessories Roller Bearing + Plain Bearing + Accessories

Linear Guides Links Motors + Accessories

Ball Screw Drive + Trapezoidal Screw Drive + Accessories

- Ball and trapezoidal screws in rolled, whirled and ground design

- Screws in special design according to your drawings

- Screws in rust-protected design

- Screws with driven nut constructed and manufactured in-house

- Complete drive systems with screw, bearing blocks and nut housing

- Bellows and centry covers as screw protection

- Screw bearings and shaft nuts

- Lubricants

Special service

Repair of ball screws of all makes within 4 days.

Screw measurement and quotation preparation.

Roller Bearing + Slide Bearing + Accessories

Roller bearing

- All types of standard roller bearings with and without housing

- Ball and roller bearing slewing rings

- High-temperature bearings

- Precision bearings for screws

- Special bearings

Slide bearings

- DU bushings

- Sintered bronze bearings

- Slide plates

- Slide bearings according to customer drawings

Accessories

- Rod ends

- Shaft nuts

- Shaft seals

- Lubricants

Linear Guides

- Shaft guides in steel, stainless steel and chrome plated

- Tolerances h6, h7, f7

- Shafts with customer-specific finishing

- Shafts with support

- Recirculating ball bearing guides

- Roller recirculating guides

- Bellow covers for guide rails

- Lubricants

Couplings, Clamps and Cardan Shafts

- Flexible couplings made of Al, steel or grey cast iron

- Metal bellows couplings made of Al or stainless steel

- Miniature couplings

- Friction couplings

- Flange couplings

- Cardan shafts

- Clamps

- Custom-made products

Motors + Accessories

It is becoming more and more important to develop cost-effective drives tailored to the application. In addition to the selection of the power transmission, e.g. gear wheel, chain, tooth belt or screw, the right combination of motor, gear and control is decisive. We will be happy to assist you in selecting the right drive concept for your needs.