Together with our customers we design the complete grinding process. In addition to the machine, this includes the supply and removal of the parts to be ground as well as the optimisation of the grinding process by selecting the right grinding wheels and coolant. On request, an automated measurement of the ground parts with evaluation and NOK shunt can also be offered.

Blumberg has built high-quality grinding machines for a wide range of products for decades. GIA takes over Blumberg in year 2010 and continues this tradition with the development of new grinding machines and grinding concepts. Our product range includes double disc grinding machines and special customized grinding machines.

GRINDING TECHNOLOGY

Grinding Concepts

GIA Services

- Spare parts

- Assessment

- Measurement + repair

- Retrofit to current technology

- Grinding process optimisation

GIA Blumberg Grinding Machines

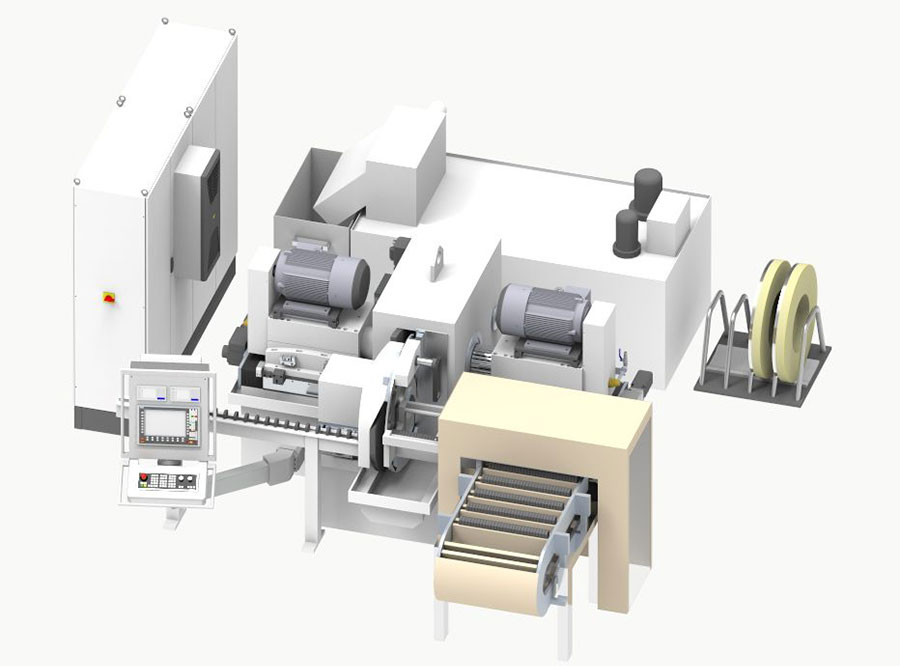

Double disc grinding machines

- Very rigid base frame in T-shape

- Generously dimensioned grinding spindles

- Curved guides for exact adjustment of the tilting

- Adjustment units for grinding spindles with prestressed roller guides and backlash-free ball screws

- Displacement measuring systems for exact positioning of the grinding spindles

- Precise, backlash-free and rigid CNC dressing system

- In-process measuring system, infeed standard 1 ym, on request 0.5 ym (post-process optional)

- Throughfeed and plunge grinding possible

- On request delivery of a fully automated grinding machine – including feed and discharge

| D660 | D760 | D900 | |

| Dimensions WxHxD in m | 3.32 x 2.05 x 2.28 | 3.32 x 2.05 x 2.28 | 3.32 x 2.05 x 2.28 |

| Weight in kg | 15,000 | 15,500 | 17,500 |

| Grinding wheel diameter in mm | 660 | 760 | 914 |

| Spindle motor power in kW | 37 / 45 | 45 | 45/55 |

| Max. workpiece dimension D in mm | 220 | 320 | 420 |

| Controller | 840D-SL | 840D-SL | 840D-SL |

Special grinding machines

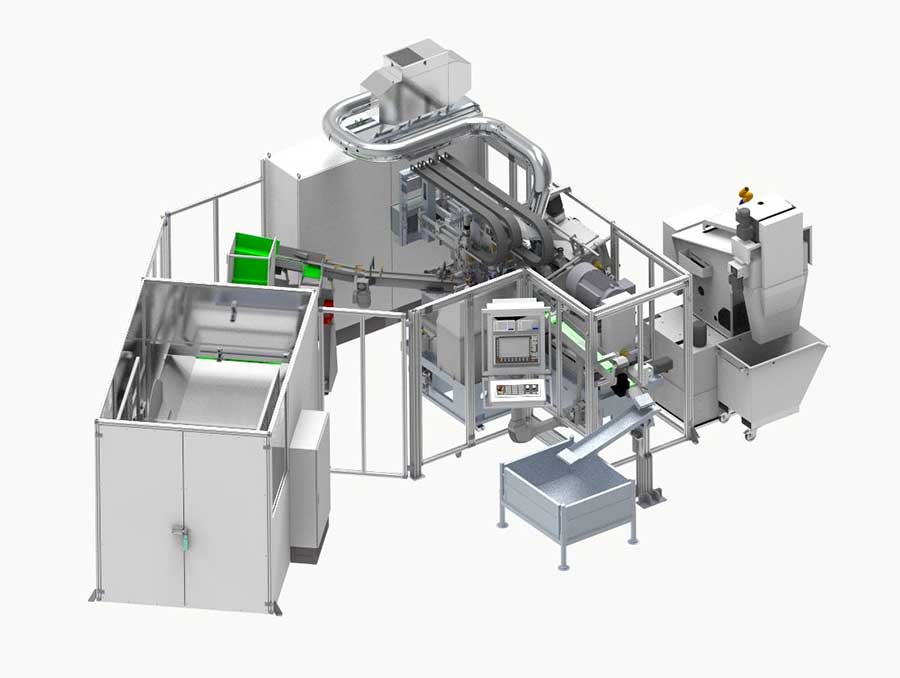

Special grinding machine for flat parts (e.g. connecting rods)

- 6-axis grinding machine

- With feed and discharge system

- Grinding wheel diameter 960 mm

- Transport wheel with exchangeable nests – easy conversion to other products

- In-process measurement

- Integrated coolant system

- All axes with servo motors and absolute encoders

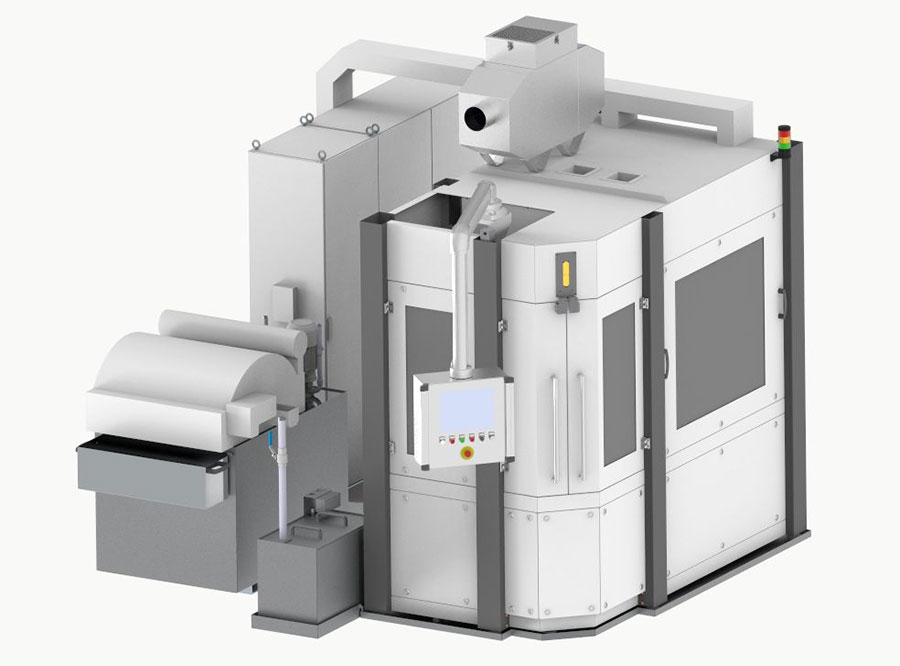

Special grinding machine for industrial blades

Compact special grinding machine for small hardened industrial blades

- 5-axis grinding machine

- Swivelling magnetic table, swivel angle programmable

- Spindle speed max. 11,600 rpm

- High-pressure flushing

- Integrated extraction system

- Integrated coolant system

- All axes with servo motors and absolute encoders

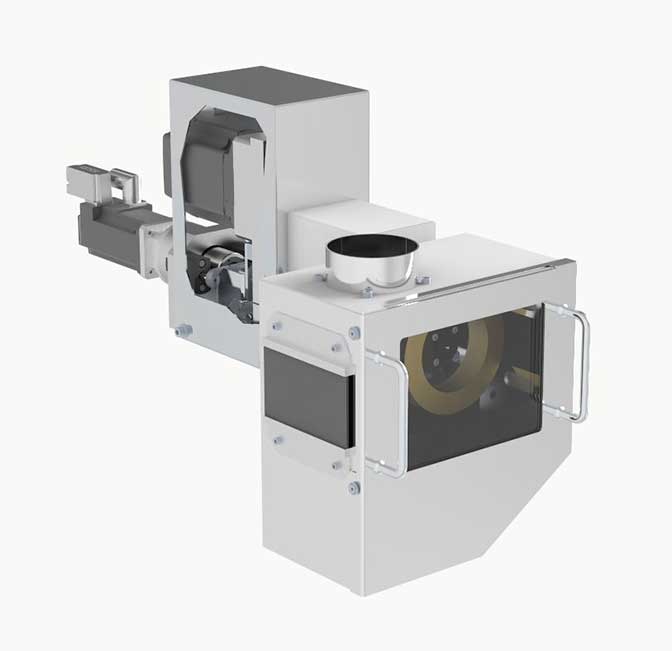

Grinding Gap Measuring Device SMP3

The further developed SPM 3 is a high-precision grinding gap measuring device. A wide range of accessories offers a multitude of measuring possibilities. The measuring device can be used in any double disc grinding machine to measure the grinding wheel geometry:

- Evaluation of the geometry of the grinding wheels in relation to each other

- Evaluation of the resulting geometry during grinding

- Evaluation of the resulting geometry after dressing

- Targeted adjustment of the tilting to optimise the grinding result

- Transfer and adjustment of an optimal grinding channel to other double disc grinding machines

- Evaluation of machine stability

- Mechanical troubleshooting

- Control of the printed circuit boards in the inlet and outlet area (option)

The SPM 3 is delivered with accessories in a sturdy aluminium case padded with foam inserts.

DEBURRING TECHNOLOGY

GIA Brushing Station DS180 Sensor

- For manual and automatic deburring

- Simple adjustment of the workpiece support / centring

- Easy to empty chip collecting container

- Connection for external extraction

- 2 brush heads

- Speed and direction of rotation of each brush separately adjustable

- Sensor for measuring the brushing force and for automatic adjustment of the brush

- The brushing force can be specified in N

- All axes with servo motor

- Use of different brushes possible (cup, disc or knot brushes)

Project example

GIA brushing station DS150 Sensor

- For automatic deburring with robot or handling

- Easy to empty chip collecting container

- Connection for external extraction

- 1 brush head

- Speed and direction of brush rotation adjustable

- Sensor for measuring the brushing force and for automatic adjustment of the brush

- The brushing force can be specified in N

- All axes with servo motor

- Use of different brushes possible (cup or disc brushes)

Project example