- Profile cross-section max. 230 x 25 mm

- Extremely stable frame with generously dimensioned linear guides

- Cycle time 6 seconds

- Very small angular error

- Small length tolerance

- Dry workpieces due to minimum quantities from coolant/lubricant device

- Integrated extraction system

- Infinitely variable speed and saw feed control

- Saw feed with ball screw

- Workpiece feed infinitely adjustable with ball screw

- All axes with servo motors and absolute encoders

GIA mbH is your innovative and reliable partner in the field of automated production.

We develop and build systems and devices that help our customers to improve their production processes. This also includes automated equipment for quality assurance. Our many years of experience in special machine construction and the use of our own modules such as linear axes or screw jacks strengthen our market position.

From project planning to realisation, we attach great importance to dialogue with our customers in order to implement the task constructively and economically.

LET'S TALK ABOUT YOUR MANUFACTURING SITUATION

Give us a call at +49 (0) 221 7174-380

COMPLETED CUSTOMER PROJECTS

Do you have any questions? Contact us, we will be happy to provide you with information.

PROJECT 3 Measuring System for Metal Sheets Completely EncapsulatedPROJECT 4 Handling for Pipes with Transport Box Changer

PROJECT 5 Handling for Screwing and Transporting Assembly PartsPROJECT 6 Robot Handling for Transporting Wire-Mesh Baskets with Gear Parts in a Cleaning System

PROJECT 1

Automated Saw for Steel Profiles

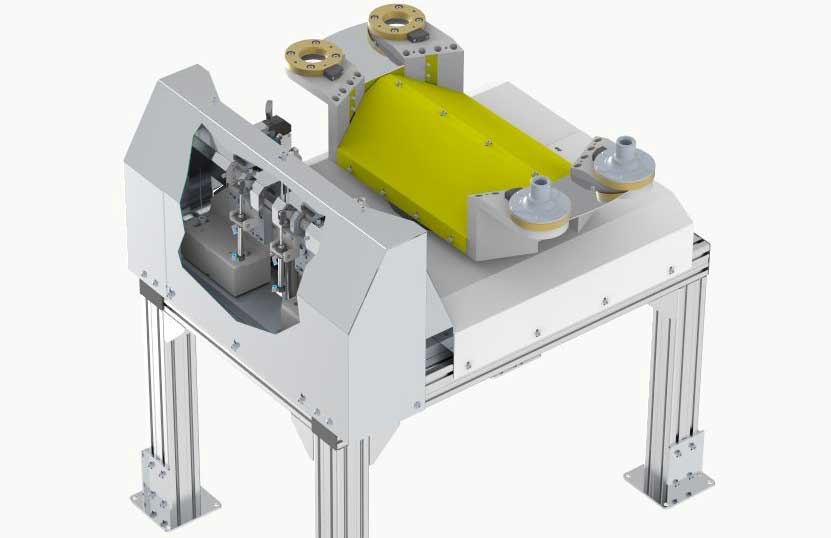

PROJECT 2

Positioning Device for Wheel Hubs

- Automatic pre-positioning of the wheel hubs for further machining

- The wheel hubs are aligned according to the angle of rotation

- All axes with servo motors and absolute encoders

- The alignment is carried out without affecting the cycle time

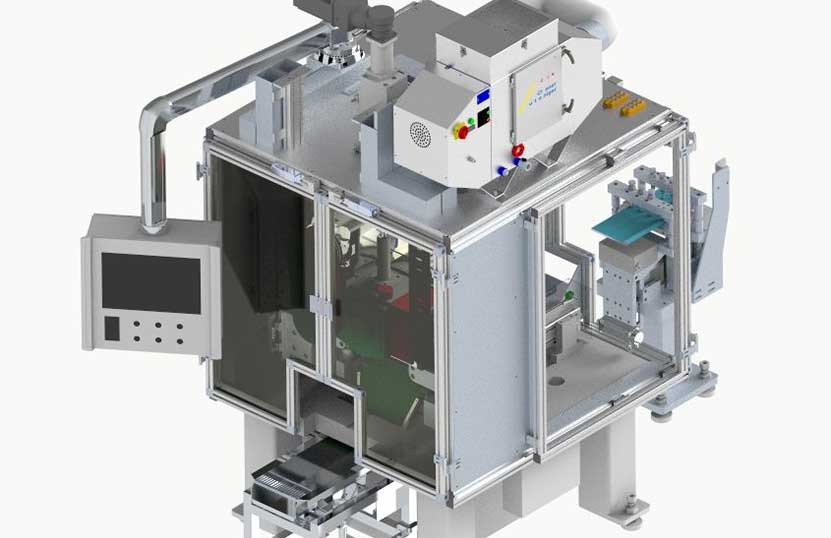

PROJECT 3

Automated Measuring System for Metal Sheets Completely Encapsulated

- Sheet dimensions max. 2200 x 4000 mm

- 4 cameras with LED lamps, individually moveable

- All axes with linear measuring systems

- Complete encapsulation with ventilation openings

- All axes with servo motors and absolute encoders

- Developed in cooperation with IMESS

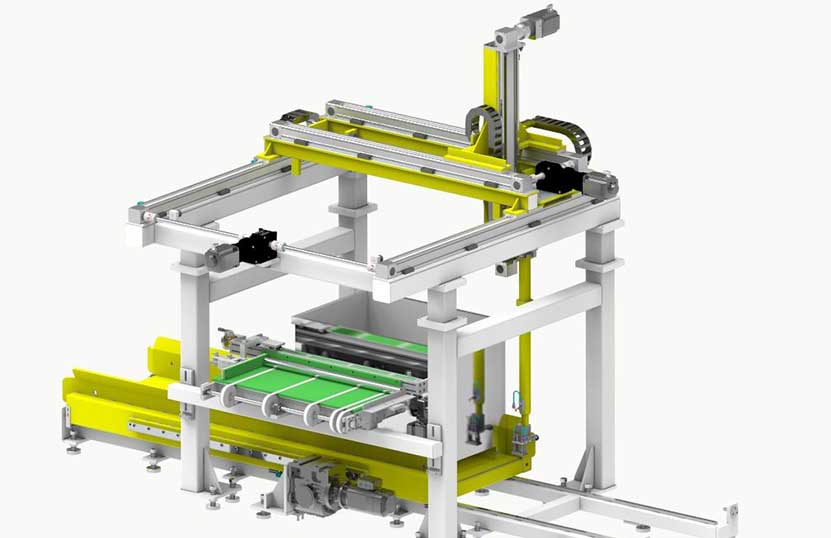

PROJECT 4

4-Axis Handling for Pipes with Transport Box Changer

- Integrated cross transport

- Stop side with spindle with measuring scale adjustable to pipe length

- Pneumatic flush pusher

- Gripper system optionally pneumatic or with magnets

- Processing of different pipe lengths and pipe diameters

- Stable transport box changing system

- All axes with servo motors and absolute encoders

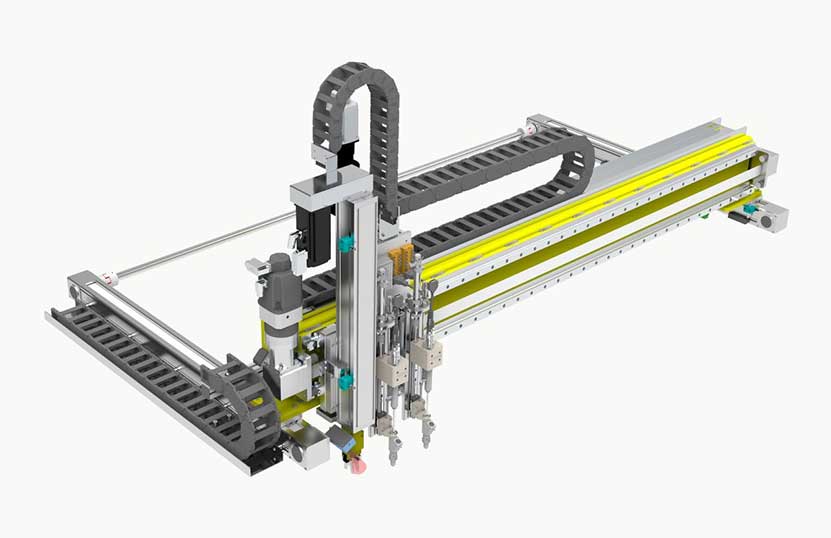

PROJECT 5

3-Axis Handling for Screwing and Transporting Assembly Parts

- 2 screw systems

- A gripper system with vision sensor for part recognition

- Z-axis with ball screw drive

- X- and Y-axis with tooth belt

- All axes with servo motors and absolute encoders

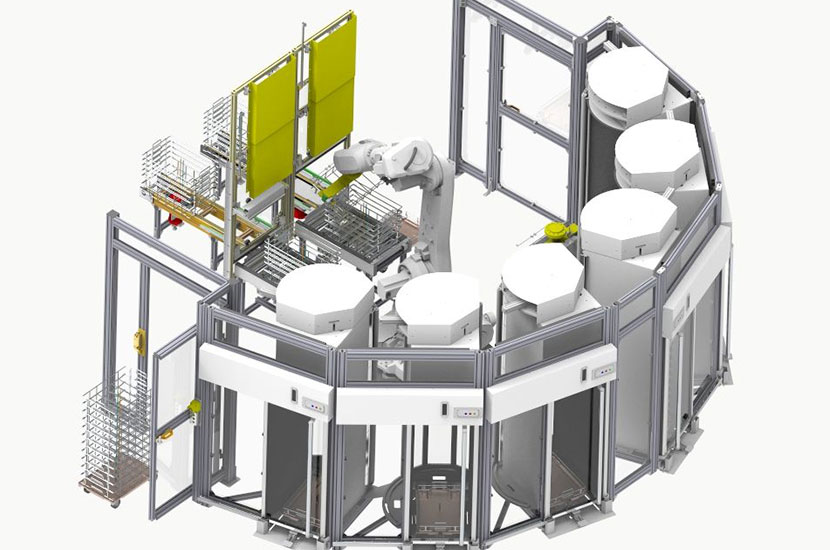

PROJECT 6

Robot Handling for Transporting Wire-Mesh Baskets with Gear Parts in a Cleaning System

- 6-axis robot from ABB

- Processing of stacked wire-mesh baskets alternately from 6 cells

- Removal and restacking of wire-mesh baskets always in the same cell

- Gripper system attached to the robot with a magnetic coupling

- Query of the magnetic coupling via sensor – immediate stop of the system in the event of a collision

- Safe Move i.e. Defined safety zones for the operator during maintenance and set-up

- Query of the floor rollers with wire-mesh baskets via sensors in each cell